What makes a stretch wrapping machine indispensable for manufacturers

Wiki Article

Improve Your Product Packaging Refine With a Trustworthy stretch wrapping machine for Optimum Performance

In the complex globe of logistics, an effective packaging procedure is an essential factor that can significantly influence a business's bottom line. The unification of a trustworthy stretch wrapping machine not just maximizes performance yet likewise ensures the honesty of products during transportation - stretch wrapping machine.Comprehending the Role of a stretch wrapping machine in Product Packaging

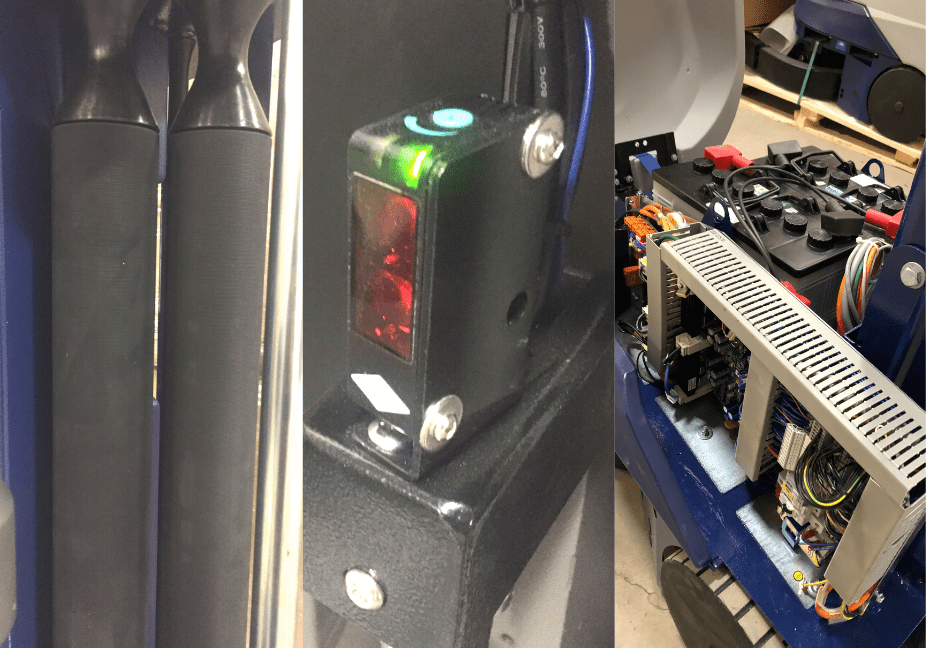

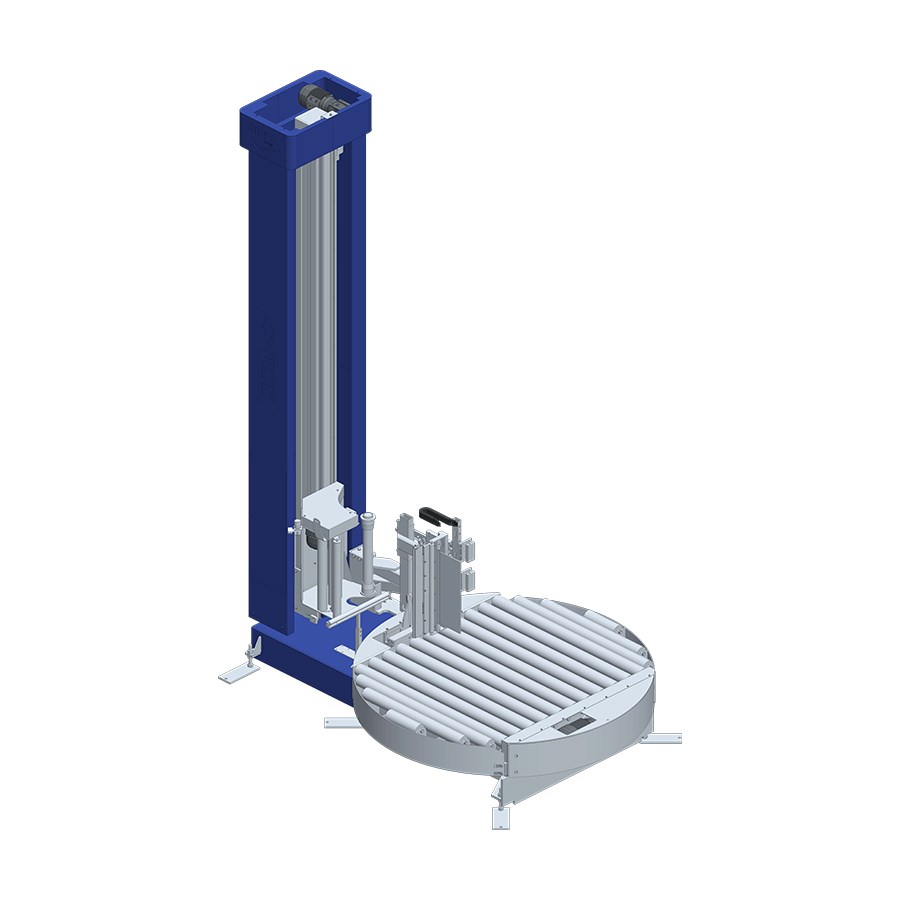

Making certain item safety and security throughout transit, a stretch wrapping machine stands as a pivotal possession in the product packaging market. Its key function focuses on encapsulating products in a safety layer of movie, therefore preserving product honesty and minimizing damages dangers throughout transport.The maker's operation is intricate yet effective. Goods are put on a rotating base while the film is untangled from a fixed roll. As the turntable rotates, the film is applied evenly over the objects, guaranteeing full coverage.

This device's importance prolongs past plain wrapping. stretch wrapping machine. It improves the piling security of goods, minimizing the chance of accidents. Even more, it safeguards products from dirt, dampness, and other environmental factors, preserving their high quality until they reach the customer

Basically, a stretch wrapping machine is an indispensable tool for organizations looking for to maximize their packaging procedure, safeguard their items, and improve their logistics procedures. Its duty is integral to the effective and efficient functioning of the modern packaging industry.

Key Features to Think About When Selecting a stretch wrapping machine

When choosing a stretch wrapping machine for packaging functions, a number of vital attributes necessitate factor to consider. These consist of evaluating the machine's performance, recognizing its lots capability, and examining its longevity and upkeep demands. An informed choice joints on an extensive evaluation of these variables.Although performance could not be the initial thing you think about when taking into consideration stretch covering devices, it is a vital element that can significantly affect your product packaging procedure. An efficient equipment can significantly lower waste, lower expenses, and enhance efficiency. When evaluating performance, consider the device's rate. A faster maker can wrap more plans in less time, improving your procedure's result. Likewise, look for programmable setups, which can personalize the wrapping procedure to fit different items, reducing unnecessary use materials. In addition, an effective machine must require very little upkeep, guaranteeing continual operation without regular disturbances. The device's power intake is one more crucial aspect, as a machine that utilizes much less power can cut operating expenses. Bear in mind, an efficient device guarantees ideal performance.

The Influence of a Reputable stretch wrapping machine on Performance Degrees

Spending in a trusted stretch wrapping machine can significantly boost performance degrees in a packaging operation. These machines automate the covering process, allowing for efficient and regular efficiency that surpasses manual covering methods.

A dependable equipment reduces downtime created by mechanical failures or upkeep needs. This guarantees a stable flow of work, preventing delays and stockpile in the manufacturing chain. Top notch stretch wrapping equipments likewise have adjustable setups for various product kinds. This versatility permits More Info services to deal with a wide series of things without lengthy manual modifications.

Furthermore, these machines need less human intervention, releasing up employees to focus on various other important jobs. This optimization of human resources can cause a rise in overall functional performance.

In essence, a trusted stretch wrapping machine is a useful investment that can enhance productivity degrees in a packaging procedure, giving substantial benefits in resource, performance, and flexibility exercise.

Ways in Which a stretch wrapping machine Minimizes Waste

A stretch wrapping machine's function in waste decrease is significant and complex (stretch wrapping machine). Not just does it lessen material usage by effectively wrapping products, but it also safeguards goods from damages throughout handling and transportation. This dual benefit cause noteworthy cost savings and advertises sustainability in the product packaging procedureLessening Product Usage

Price and Time Cost Savings: The Economic Benefits of a stretch wrapping machine

In addition, the device's regular covering strategy minimizes product damage, reducing substitute prices and boosting client satisfaction. Using a stretch wrapping machine likewise results in an extra foreseeable budgeting procedure, as the amount of stretch film utilized per pallet corresponds, unlike hand-operated covering which can differ greatly.

Inevitably, the cumulative financial see here now savings in labor, materials, and potential product loss make the initial investment rewarding. In the long term, organizations can accomplish substantial financial advantages by integrating a stretch wrapping machine right into their product packaging procedure.

Verdict

Although efficiency may not be the first point you think of when thinking about stretch covering machines, it is a crucial element that can dramatically affect your packaging procedure. The equipment's power intake is one more essential aspect, as a machine that uses less energy can reduce operating expenses. Additionally, a device sustained by a detailed warranty and exceptional customer service can ease possible problems in preserving the device's ideal efficiency.To comprehend the means in which a stretch wrapping machine reduces waste, one should first take into consideration the cutting-edge style of these machines. In this method, stretch covering makers not only improve the quality of product packaging yet likewise cultivate a more reliable and environmentally-friendly process, demonstrating their crucial role in contemporary product packaging procedures.

Report this wiki page